BUILT FOR PERFORMANCE TODAY. READY FOR GROWTH TOMORROW.

Highlights at a glance:

- Powder-coated industrial steel chassis for long-term durability

- High-precision, absolute encoder drives for perfect positioning

- Open software docking for easy programming

- 16-position rotary tool changer

- 9/18-position vertical drilling head

- Matrix vacuum table with precision zoning, software-controlled solenoids

- Engineered for seamless automation upgrades: offload conveyors, lifting tables, Power Label systems

Retrofit ready, allows the machine to grow with you.

PANEL CENTERS ENGINEERED FOR EFFICIENCY. BUILT FOR LASTING VALUE.

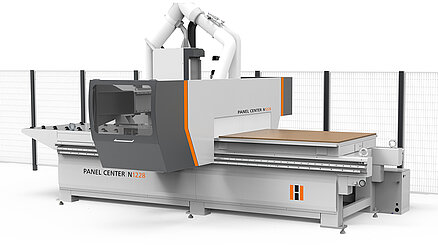

Panel Center N 1228 Classic

Fully equipped core machine

- Compact footprint

- Minimum initial investment

- Manual loading — manual offload

- Integrated pusher

- Powerful PC with open software docking

- Ready for future automation

Panel Center N 1228 Push

Integrated pusher

- Compact to medium footprint

- Mid-range investment

- Integrated pusher

- Motorised offloading conveyor

- Semi-automatic offloading

- Powerful PC with open software

- Ideal for growing businesses

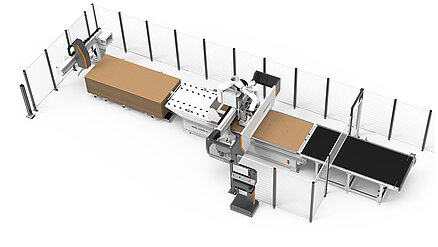

Panel Center N 1228 Lift

Fully automatic, high-output solution

- Complete automation package

- Labelling before machining

- Automated job list

- One-operator supervision

- Full safety zone protection

- Powerful PC with open software

- For High-volume production

TECHNICAL SPECIFICATIONS HOLZ-HER PANEL CENTER NESTING LINE

- Panel Center

- N 1228

- N 1631

- Board Size

- 2800 x 1240

- 3100 x 1550

- Spindle

- 12 kW / 24.000 rpm

- 12 kW / 24.000 rpm

- Tool Changer

- 16-position rotary

- 16-position rotary

- Drill Block

- 9 vertical spindles

- 18 vertical spindles

- Vacuum Zones

- Programmable

- Programmable

- Vacuum pump

- 250m3/h

- 2 x 250m3/h

- Software

- open CAM

- open CAM

- Automation

- Classic / Push / Lift

- Classic / Push / Lift

HIGHLIGHTS OF THE HOLZ-HER PANEL CENTER N 1228

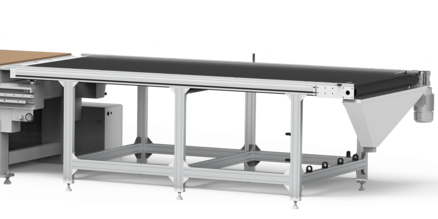

Outfeed Conveyor Belt

An integrated motorized outfeed conveyor smoothly removes finished parts from the working area, reducing manual handling and increasing productivity. The conveyor is designed for scratch-free, damage-free part transport, ready for downstream operations or immediate packing.

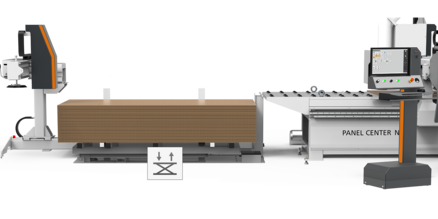

Lifting Table (Automatic Models)

A heavy-duty scissor-lift table automatically loads raw boards onto the machine, perfectly synchronized with the Power Label system. It minimizes operator strain and speeds up production cycles, especially in high-throughput environments.

Power Label System (Automatic Models)

Prints and applies labels to panels before machining, ensuring parts can be clearly identified during assembly. The system is seamlessly integrated with the nesting software , boosting accuracy and eliminating sorting errors.

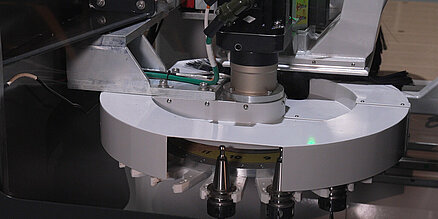

16-Position Rotary Tool Changer

Mounted directly on the beam, this high-speed carousel changer reduces tool change time dramatically compared to linear changers. ISO or HSK tool holders are supported, giving you industrial-grade flexibility for different cutting, grooving, and drilling operations.

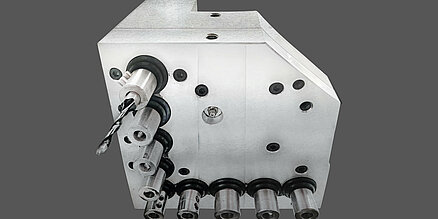

9/18-Spindle Drilling Head

Equipped with 9 vertical spindles (5 in X, 4 in Y) or 18 vertical spindles (11 in X, 7 in Y), this drill block makes cabinet and shelf drilling fast, accurate, and highly efficient. Controlled directly through the software interface, it can handle standard line boring, hinge holes, and more.

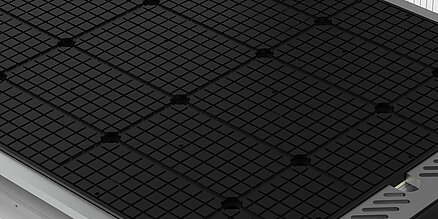

Vacuum Matrix Table and high performance pump

A precision-milled vacuum matrix table with multiple programmable zones provides secure clamping for small and large workpieces alike. The powerful rotary vane vacuum pumps ensure constant, reliable hold-down force — even with porous materials — to maintain cutting quality and repeatable accuracy.

Seamless Office-to-Machine Nesting with Top-tier CAD/CAM Software

Cabinet Vision - Computed-aided manufacturing

Complete cabinet engineering solution: design cabinets, closets, drawers, doors, stretchers—all in one environment

Modular platform: includes xOptimizer for material-saving layouts, Machining for automated CNC outputs, and xRendering for photorealistic visuals.

- Design & Nest in Cabinet Vision using CAD, rendering, costing & optimization modules.

- Export G-code or native machine files directly to the Panel Center via OSAI’s open docking.

- Verify & Simulate 3D paths on-screen to catch errors and predict production time before machining.

- Produce high-precision parts with unmatched repeatability in a compact footprint.

- Scale smoothly—add conveyors, lifting tables, or Power Label to reduce manual work

Learn more about Cabinet Vision

DDX – CAD/CAM software for CNC machining

The DDX ultimate CAD/CAM tools for professionals.

- DDX solutions are easily integrated for a seamless communication between the CAD and CAM

- For an optimal shop floor handling, our tools can manage multi-material projects. Pass from the design stage to processing and print file export in just few clicks.

- With our CAD/CAM offer, we can meet the market’s diverse demands effectively, providing highly customizable software.

- Unmatched nesting accuracy for better efficiency and material management.

DDX EasyWOOD Nest XDesignPRO

- Transform your creative process with our easy-to-use parametric programs. No shape will be impossible, and you can simply create your project from scratch.

- Manage your production line.

- Nest your wooden pieces intuitively thanks to our dedicated module and save material, up to 40%.

- Handle the most diverse materials for a higher level of versatility.

- Perfect for beginners or more experienced woodworking professionals.

Alphacam – Intelligent and Versatile CAD/CAM SOFTWARE

Designed for woodworking, metal & stone – fully adaptable to diverse CNC nesting needs. For powerful automation.

Powerful automation: from toolpath generation to complex machining, Alphacam streamlines repetitive operations. Boost Productivity in 4 Easy Steps:

- Design & Nest: Alphacam delivers intelligent nesting and optimized toolpaths for your panel programs.

- Simulate: Screen-based previews reduce errors and ensure precise outcomes.

- Transfer: Send production-ready programs directly to HOLZ‑HER’s OSAI controller.

- Machine: Load, label, and offload panels with precision — minimal operator intervention, maximum consistency.

- Maximise efficiency: save material & time.

BOOK YOUR PERSONAL DEMO TODAY

Experience HOLZ-HER precision live. Let our experts show you how the Panel Center line transforms your production.

ABOUT WEINIG & HOLZ-HER UK

Backed by WEINIG's global group, HOLZ-HER brings decades of CNC expertise to the UK with fully certified technicians, spare parts, and support centres.

MICHAEL WEINIG (UK) Ltd.

HOLZ-HER Headquarters United Kingdom

5 Blacklands Way

Oxon OX14 1DY Abingdon

United Kingdom

E-Mail: service.uk(at)weinig.com

Phone: +44 1235 557600