BUILT FOR PERFORMANCE TODAY. READY FOR GROWTH TOMORROW.

Highlights at a glance:

- Powder-coated industrial steel chassis for long-term durability

- High-precision, absolute encoder drives for perfect positioning

- Open software docking for easy programming

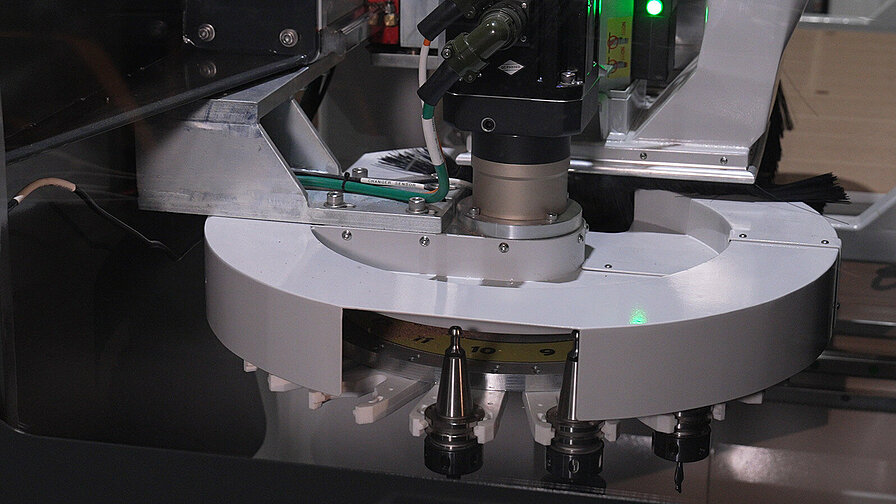

- 16-position rotary tool changer

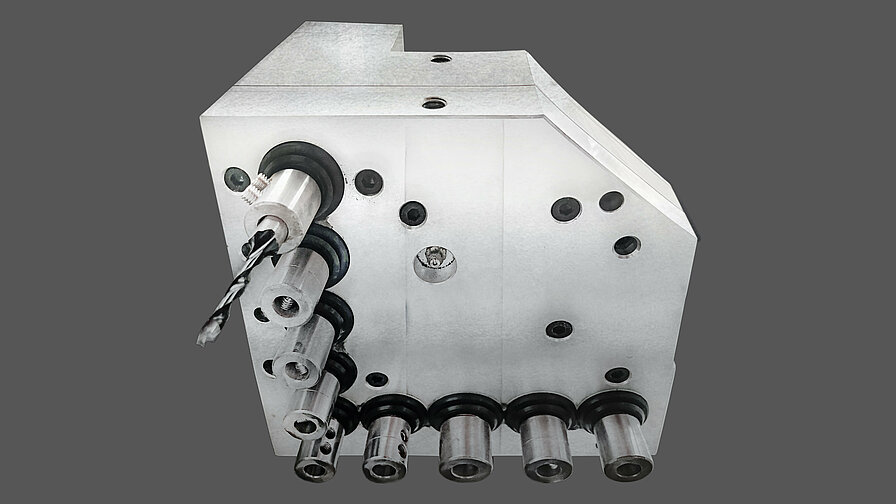

- 9/18-position vertical drilling head

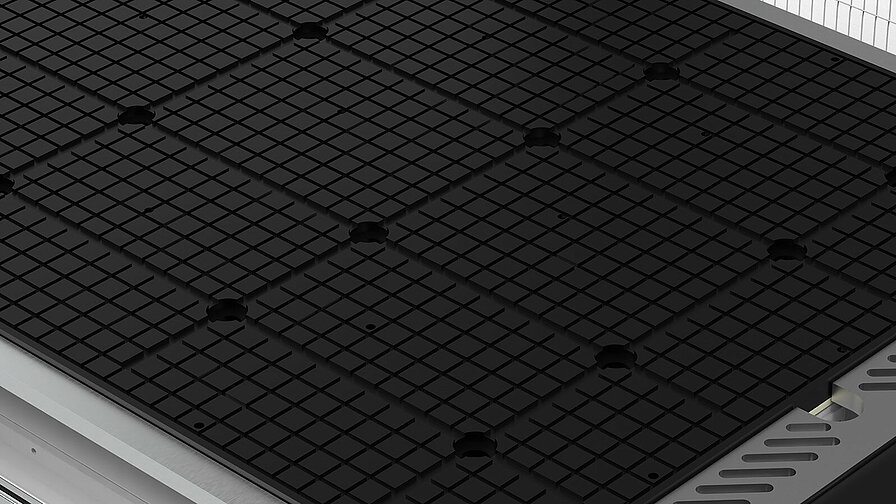

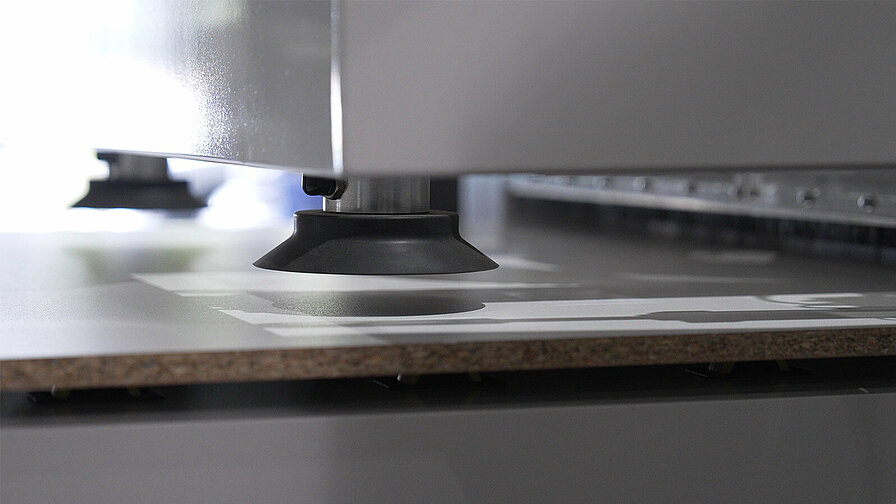

- Matrix vacuum table with precision zoning, software-controlled solenoids

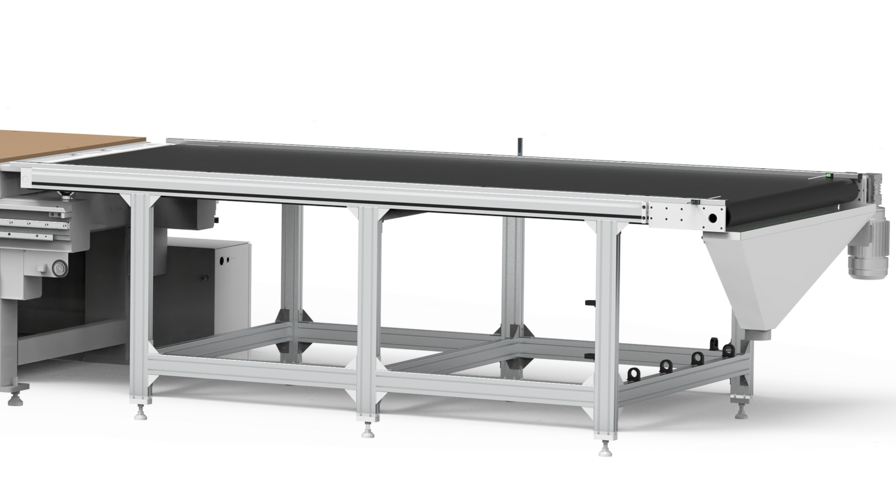

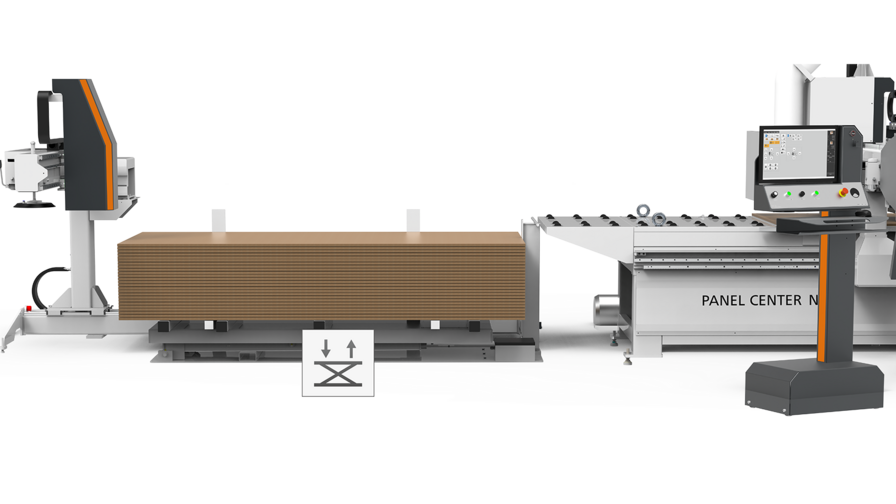

- Engineered for seamless automation upgrades: offload conveyors, lifting tables, Power Label systems

Retrofit ready, allows the machine to grow with you.

OUR PANEL CENTER MODELS

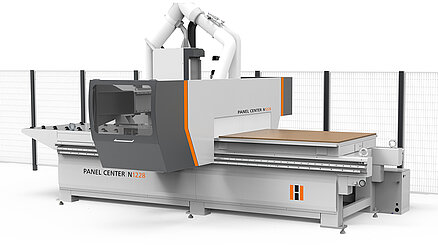

Panel Center N 1228 Classic

Fully equipped core machine

- Compact footprint

- Minimum initial investment

- Manual loading — manual offload

- Integrated pusher

- Powerful PC with open software docking

- Ready for future automation

Panel Center N 1228 Push

Integrated pusher

- Compact to medium footprint

- Mid-range investment

- Integrated pusher

- Motorised offloading conveyor

- Semi-automatic offloading

- Powerful PC with open software

- Ideal for growing businesses

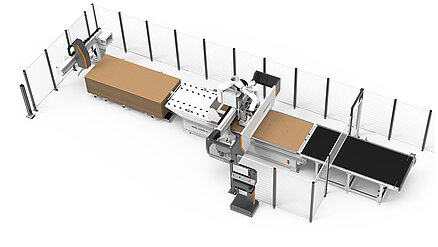

Panel Center N 1228 Lift

Fully automatic, high-output solution

- Complete automation package

- Labelling before machining

- Automated job list

- One-operator supervision

- Full safety zone protection

- Powerful PC with open software

- For High-volume production

Technical Specifications HOLZ-HER Panel Center Nesting Line

- Panel Center

- N 1228

- N 1236

- N 1836

- Board Size

- 2800 x 1240

- 3600 x 1240

- 3600 x 1840

- Spindle

- 12 kW / 24.000 rpm

- 12 kW / 24.000 rpm

- 12 kW / 24.000 rpm

- Tool Changer

- 16-position rotary

- 16-position rotary

- 16-position rotary

- Drill Block

- 9 vertical spindles

- 9 vertical spindles

- 9 vertical spindles

- Vacuum Zones

- Programmable

- Programmable

- Programmable

- Vacuum pump

- 250m3/h

- 2 x 250m3/h

- 2 x 250m3/h

- Software

- open CAM

- open CAM

- open CAM

- Automation

- Push / Lift

- Push / Lift

- Push / Lift

Seamless Office-to-Machine Nesting with Top-tier CAD/CAM Software

Cabinet Vision - Computed-aided manufacturing

Modular platform: includes xOptimizer for material-saving layouts, Machining for automated CNC outputs, and xRendering for photorealistic visuals.

- Design & Nest in Cabinet Vision using CAD, rendering, costing & optimization modules.

- Export G-code or native machine files directly to the Panel Center via OSAI’s open docking.

- Verify & Simulate 3D paths on-screen to catch errors and predict production time before machining.

- Produce high-precision parts with unmatched repeatability in a compact footprint.

- Scale smoothly—add conveyors, lifting tables, or Power Label to reduce manual work

Learn more about Cabinet Vision

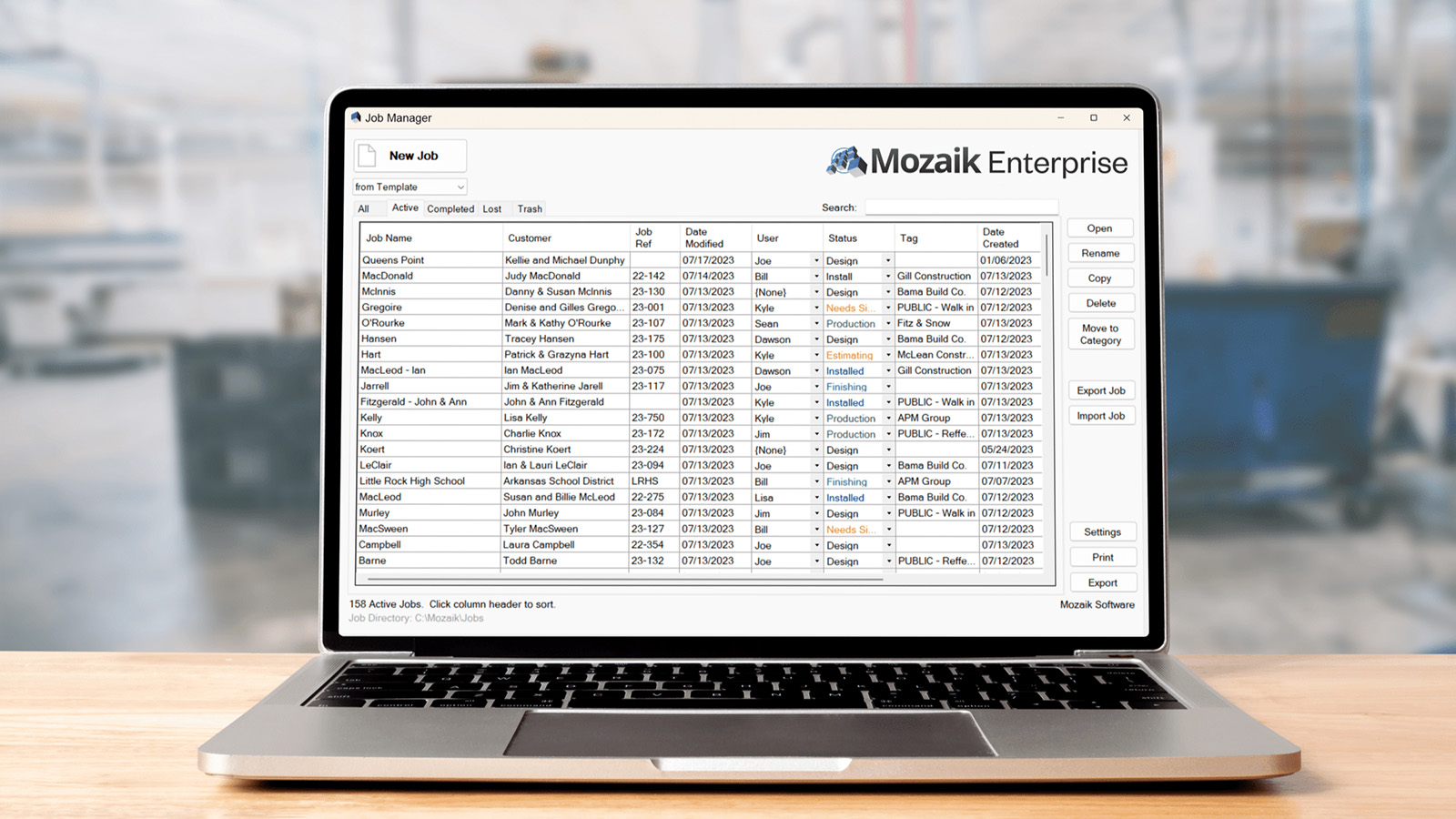

Mozaik Manufacturing / CNC / Enterprise

Quick launch & local support: Start in days, not weeks, with expert training and flexible subscription models in Australia

- Advanced CNC capabilities: True-shape nesting, flipside machining, automatic hardware boring, dovetail drawers, and G‑code with free post-processors

- Scalable options: Upgrade as needed—for job scheduling and multi-machine control

- Powerful nesting & optimization tools: Reduce material waste and cut costs

- Integrated labelling & customization

- No CAD experience needed, plus a three-month trial and one-on-one setup

Alphacam – Intelligent & Versatile CAD/CAM

Powerful automation: from toolpath generation to complex machining, Alphacam streamlines repetitive operations. Boost Productivity in 4 Easy Steps:

- Design & Nest: Alphacam delivers intelligent nesting and optimized toolpaths for your panel programs.

- Simulate: Screen-based previews reduce errors and ensure precise outcomes.

- Transfer: Send production-ready programs directly to HOLZ‑HER’s OSAI controller.

- Machine: Load, label, and offload panels with precision — minimal operator intervention, maximum consistency.

- Maximise efficiency: save material & time.

Book Your Personal Demo Today

Experience HOLZ-HER precision live. Let our experts show you how the Panel Center line can transform your production.

About HOLZ-HER & Weinig Australia

Backed by Weinig’s global group, HOLZ-HER brings decades of CNC expertise to Australia with fully certified technicians, spare parts, and support centres from Melbourne to Perth.

MICHAEL WEINIG AUSTRALIA PTY LTD

3 Widemere Road

Wetherill Park NSW 2164

Australia

Phone: +61 2 9609 5911

Freecall: 1800 736 460

Times: Mon-Fri 08:00am-16:30pm

Email: sales.au(at)weinig.com